|

Read Rob Woodland's article in Plumbing+HVAC for a brief intro into the UV Disinfection Space! |

Many of us have heard of the term “ultraviolet”, however the likelihood was that it was in reference to exposure to the sun rather than its disinfection capabilities of drinking water and other fluids! As early as 1877, two British researchers, Downes & Blunt discovered the dramatic ability of sunlight to destroy and provide for an effective means of treating bacterial infections. In 1901, Cooper-Hewit's mercury arc invention was unveiled to the world, followed by the Quartz-Burner as the first intensive UV source by Mich in 1906. The first fused silica quartz arc tube was developed by a pair of Germans, Kuch & Retschinsky in 1906. They managed to get more light output from a quartz glass tube as compared to standard glass because the quartz glass tube could endure the higher operating temperature associated with a higher tube pressure that was required to generate more light output. Quartz was also the ideal choice of material because it was less chemically reactive to the hot chemicals and gases encountered within the lit arc tube. This ultimately led to the first full-scale UV disinfection apparatus by Henri and coworkers in France in 1910.

There are two main types of disinfection; chemical and physical. Chemical disinfection is when a chemical is added to a substance, depending on the substance being disinfected, whereas with physical disinfection no chemical is added.

One of the most popular chemical disinfectants is chlorine. Most drinking water facilities use chlorine in order to control microorganisms in the water that is being distributed to the public. It is applied by adding a known concentration of the chemical to a volume of water and then mixing throughout. The chlorine immediately targets the microorganisms killing them, however there is free chlorine remaining in the water that was not used. This free chlorine can then bond with other compounds that may be present in the water, like organics. The water now has the potential to smell different, taste different, the pH can change and various compounds could possibly have been formed due to reactions happening in the water. In other words chlorine is very effective at treating microorganisms in water however it can cause a great deal of change to the water that is being treated.

There are various forms of physical disinfection such as filtration, the boiling of water and ultraviolet disinfection. None of these methods add chemicals to the water and no new compounds will be formed. UV disinfection is a form of physical disinfection.

For water treatment, the power of the sun artificially lies inside a mercury vapour lamp. Similar to a fluorescent light tube, a mercury vapour lamp (UV lamp) emits its spectral output at 253.7 nm, a wavelength that is very close to the 265 nm wavelength that is considered the optimal for microbiological inactivation.

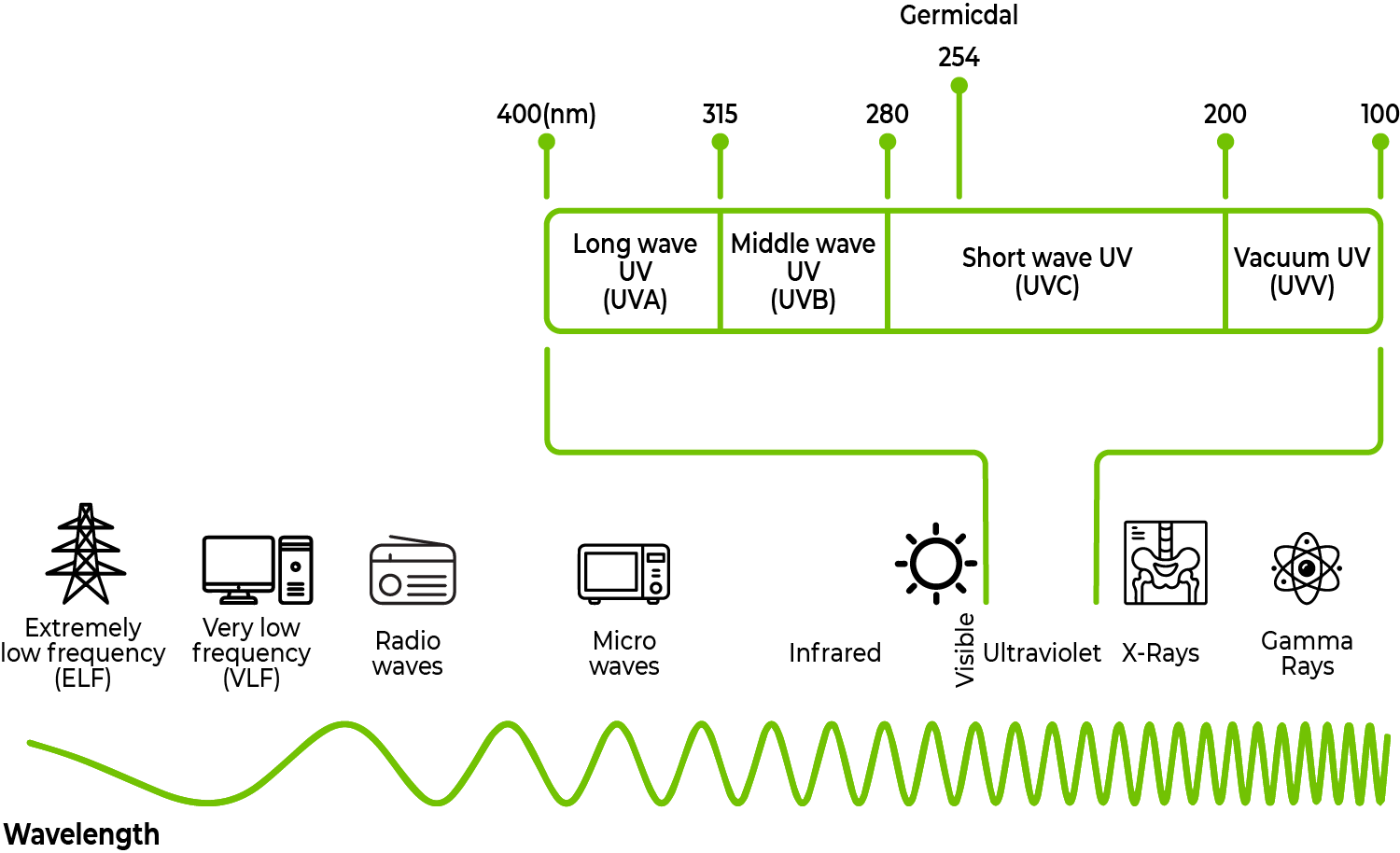

To understand the functionality of a UV lamp, one must first understand the electromagnetic spectrum. The electromagnetic spectrum (ES) is a range of all possible frequencies of electromagnetic radiation and extend from low frequencies used for modern radio, to gamma radiation at the short-wavelength end, covering wavelengths from thousands of kilometers down to a fraction of the size of an atom. The long wavelength limit is essentially the size of the universe!

Ultraviolet light is electromagnetic radiation that lies between visible light and x-rays and is comprised of four basic segments. The shorter the wavelength, the higher the energy and as a result, vacuum UV (UVV) lies in the 100-200 nm wavelength. On the opposite end of the UV scale lies long wave UV (UVA) which has the lowest energy output and lies between 315-400 nm. Middle wave UV (UVB) have wavelengths between 280-315 nm and have more energy than long wave UV. For disinfection purposes, it is the short wave UV (UVC) that we are most interested in as its wavelength covers 100 - 280 nm which covers the 265 nm optimal wavelength mentioned earlier for microbiological inactivation.

UV water treatment systems are designed to disinfect* viruses, bacteria, and protozoa that can be found in untreated water. As water flows through the UV reactor, it is exposed to UV-C light. During this process, the DNA of organisms are changed, preventing them from replicating and rendering them inactive.

As mentioned earlier, current UV systems use mercury vapour lamps to create UV energy. These lamps can be divided into two sub-categories, the low-pressure (LP) lamps and the medium-pressure (MP) lamps.

Low-pressure lamps are monochromatic in nature, emitting energy at a single wavelength. They can be further subdivided into three subgroups:

• Standard output (LP) UV lamps have been the “industry standard” for many years, in part due to their high electrical efficiency (up to 40% of their electrical power is converted to UV). Their ambient temperature should not exceed 40°C/104°F.

• High output (HO) UV lamps are typically used for systems in a commercial application. Their output is approximately twice that of standard germicidal lamps. Their UVC output is related to ambient temperature.

• Amalgam (AM) UV lamps offer three to four times higher power density than other lamp types. They are designed for stable operation over wide ambient temperature range (4°C - 40°C). They are the preferred lamp choice for long-term applications with low or no cycles. Due to these characteristics amalgam lamps are typically used in commercial and municipal treatment systems, including in LUMINOR’s Rainier and Everest product lines.

Medium-pressure (MPUV) lamps offer the highest power density currently available in the market, but their electrical efficiency is low and operating temperature is high, making them unsuitable for residential and light commercial applications.

At LUMINOR, all three low pressure lamp technologies are used. In addition, our lamps are manufactured with a proprietary technology which provides a consistent UV output over the life of the lamp.

UVC LED

An emerging technology is UVC LED, using light emitting diodes as the energy source instead of lamps. LUMINOR’s Glacier point of use systems use this technology.

UV dose is the total amount of UV intensity multiplied by the amount of time the water is being exposed to the UV light. Dose is commonly expressed in mJ/cm², with UV water treatment systems commonly sized to provide a dose of 30 or 40 mJ/cm². UV dose is affected by many variables including flow rate, UV Transmittance (UVT) and water quality. Determine your maximum flow rate and perform a water quality test to guide you to a correctly sized UV water treatment system.

There are many different bacteriological contaminants that can be found in drinking water, many of which are effectively treated with UV. Each requires a different level of UV energy (dose) for disinfection. For example, due to genetic differences E.coli (6.6 mJ/cm² ) will require a slightly different dose of UV light to be inactivated than Giardia lamblia or Cryptosporidium (both 10 mJ/cm²).

Treating viruses can require higher UV doses that typically can be found in residential UV systems, so supplementary treatment may be required if this is a concern.

Please see the Microbiological Destruction Chart for a complete listing of UV dose levels required for inactivation.

|

|

|

|

|

| E. Coli | B. Subtilis | Cryptosporidium | Legionella | Giardia lamblia |

UV Reactor

The UV reactor or chamber is the component that physically houses the lamp and sleeve and is where the water is irradiated by the UV lamp.

UV Lamp

The ultraviolet lamps provide the necessary UV energy to facilitate the disinfection process. Regardless of the lamp chosen, they must be insulated from direct water immersion by a quartz sleeve. ![]()

The energy given off by a UV lamp is extremely harmful to the naked eye and one should never look directly at an illuminated UV lamp.

Controller

The controller houses both the ballast (for current control which controls the lamp) and electronics to control those functions of the UV system such as displays, lamp change reminders, and buzzers.

Although not designed to be installed outside, exposed to the elements, the controller should be as watertight as possible (controllers with direct venting should be avoided). The controller will come with enough cable to conveniently attach to the reactor and should be provided with a method to easily install it to the wall. It is also extremely important to look for electrical certification such as CSA and CE.

Quartz Sleeve![]()

The quartz sleeve provides a barrier between the UV lamp and the water.

Sensor

On the 6.1 series systems, a UV intensity monitor is included. This alerts the user of any change in performance.

UV is a rapidly growing segment in the water treatment industry today. It is widely accepted around the globe for the treatment of microbiologically contaminated waters.

As a manufacturer, LUMINOR is poised to adapt and utilize any new technologies as they relate to UV or water treatment in general. We work closely with others in the industry who are developing new technologies, such as those in the LED industry. LUMINOR is committed to providing their customers with the latest technological innovations at the most economical price. The future is definitely bright!

Skip to main content

Skip to main content